Screw Conveyor with Enlarged Loading Hopper

An excellent solution for the quick unloading of trailers equipped with discharge openings.

Grain is directly discharged into the hopper and then transported by the screw conveyor. This transport method minimizes the need for manual handling.

These conveyors are used in:

- Agriculture

- Warehouses

- Feed production facilities

- Animal farming

The conveyor features a low-positioned bottom drive, which enhances stability and reduces stress on the tubular segments.

The discharge height is manually adjustable using a crank, with a gear ratio designed for easy and safe lifting and lowering of the conveyor.

The conveyor is built on a frame-based chassis, made of solid steel profiles, ensuring high stability during operation and transport.

These conveyors are large, high-capacity transport units with a large loading hopper, and a significant advantage of their design is the ability to attach the device to a tractor for easy transport around the farm.

Gallery

Key Features of the Conveyor:

- High transport capacity – 30 and 50 t/h

- Operation at variable angles with convenient winch adjustment

- Sturdy frame-based chassis

- Modular design for flexibility

- Adjustable loading hopper height (2 × 1 m)

- Increased durability and quiet operation – bearings and grease fittings in each segment

- Large wheels suitable for all road types, with a tractor hitch

- Detachable and attachable drawbar for easy tractor transport

- Adjustable transport efficiency with a shutter

- Hot-dip galvanized for increased durability with a thick zinc coating

- Adapted for loading grain silos through the top cover opening

- Low purchase and operating costs compared to other transport equipment

Technical Specifications

| CONVEYOR SYMBOL | TUBE DIAMETER (mm) | CAPACITY (t/h) | MOTOR POWER (kW) | MIN. LENGTH (m) | MAX. LENGTH(m) |

|---|---|---|---|---|---|

| 200/10-12/OC-DR | 200 | 30 | 7,5 | 10 | 12 |

| 200/12-14/OC-DR | 200 | 30 | 9 | 12 | 14 |

| 250/10-12/OC-DR | 250 | 50 | 11 | 10 | 12 |

| 250/12-14/OC-DR | 250 | 50 | 11 | 12 | 14 |

Ordering Information

When placing an order, please refer to the conveyor symbol, e.g., 250/10-12/OC–DR, where:

- 250 indicates the diameter of the conveyor tube in mm

- 10 is the minimum conveyor length in meters

- 12 is the maximum conveyor operating length

The 12 m length is achieved by purchasing an additional extension segment.

- OC = Hot-dip galvanized conveyor

- DR = Bottom drive, with material intake through the loading hopper, and a frame-based chassis

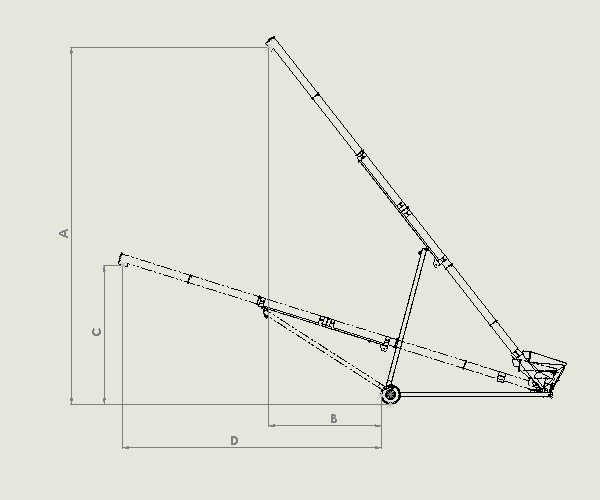

| Tube Length(m) | A | B | C | D |

|---|---|---|---|---|

| 10 | 7,5 | 1,6 | 3,1 | 5,2 |

| 12 | 9 | 3,1 | 3,7 | 7,1 |

| 14 | 10,5 | 4,6 | 4,3 | 9 |

Extension Segments

| Segment Symbol | Nominal Length(m) | Tube Diameter (mm) | Coating |

|---|---|---|---|

| 200/1/OC | 1 | 200 | Galvanized |

| 200/2/OC | 2 | 200 | Galvanized |

| 250/1/OC | 1 | 250 | Galvanized |

| 250/2/OC | 2 | 250 | Galvanized |

When placing an order, please refer to the segment symbol, e.g., 250/2/OC, where:

- 250 indicates the diameter of the conveyor tube in mm

- 2 represents the segment length in meters

- OC = Hot-dip galvanized conveyor

Additional Equipment

Extension Segment

Rotating Discharge Chute

Hopper Cover

Swivel Wheel Set

Award-Winning Product at Trade Fairs!